Technology Spotlight: Episode 16

Why water-soluble polyimide varnishes are your best choice for electrode protection in Li-Ion battery design.

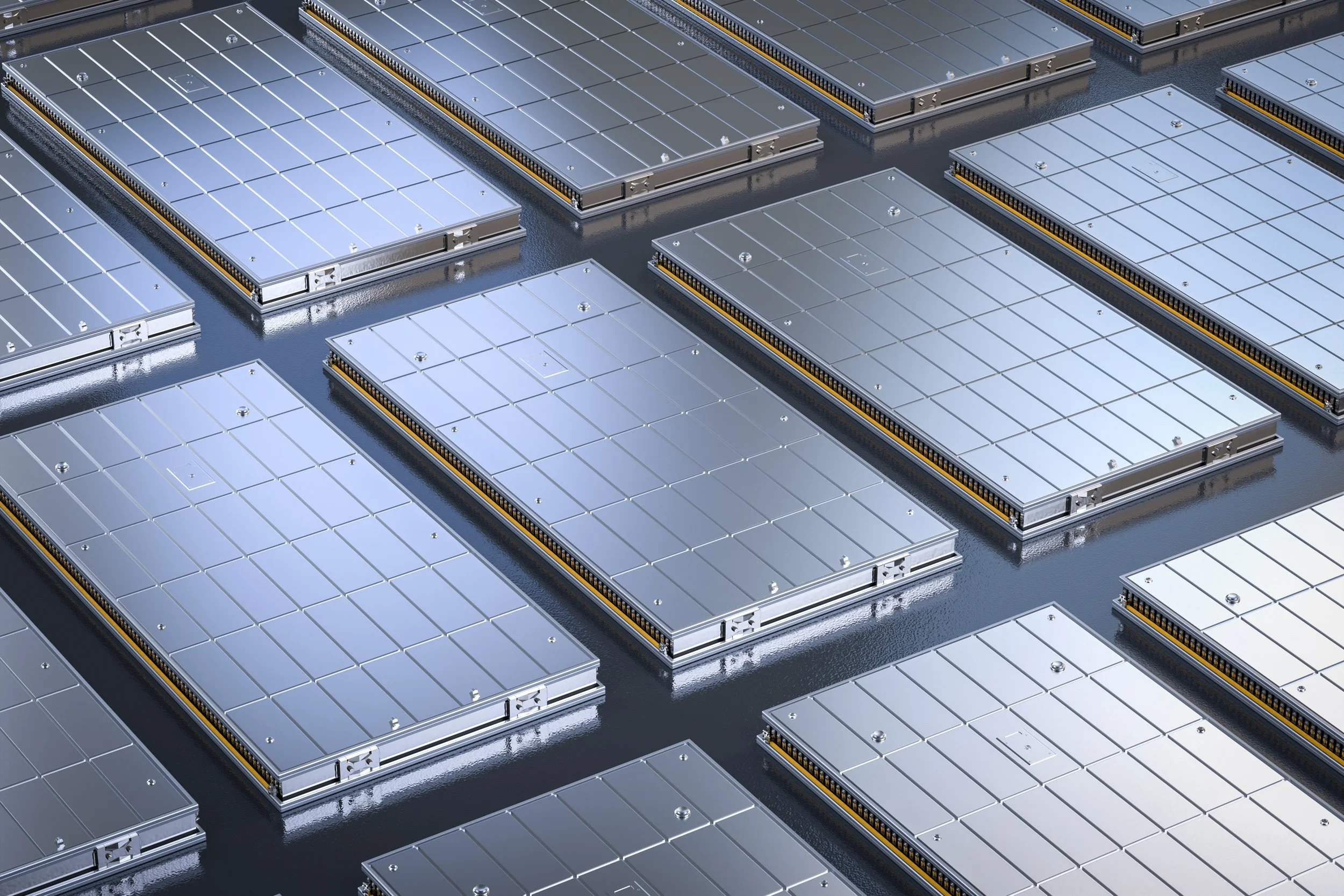

Image: Shutterstock

Polyimide varnishes have emerged as high-performance coatings for lithium-ion battery electrodes, valued for their exceptional heat resistance, chemical stability, and film-forming versatility. A lithium-ion battery, in its simplest structure, consists of four core components: a cathode, typically composed of lithium transition metal oxides; an anode, often graphite or silicon-based materials; a separating membrane; and a liquid or gel electrolyte facilitating ionic transport. During charging, lithium ions migrate from the cathode through the electrolyte to the anode’s structure, and the reverse occurs during discharge. Optimal operation of this process relies on components that maintain structural and interfacial stability under repeated cycling and elevated temperatures.

Polyimide-based coatings serve a crucial role in electrode stabilization. Derived from polyamic acid precursors, these coatings imidize upon curing to form films that are thermally stable above 300 °C and chemically inert against reactive electrolytes. Polyimide varnishes ensure consistent adhesion between electrode films and current collectors such as copper or aluminum, while also accommodating mechanical stress from volume expansion in high-capacity silicon anodes. Among the leading developments in this field are water-soluble varnish formulations specifically optimized for lithium-ion battery electrodes. These materials exhibit enhanced adhesion, chemical durability, and flexibility to mitigate cracking during cycling, a common limitation of alternative binders including acrylics and polyvinylidene fluoride (PVDF) binders [1][2].

Recent research underscores multiple roles of polyimide coatings in improving cell performance. Thin, continuous polyimide films on cathode surfaces have been shown to suppress parasitic reactions at high voltages by acting as electronic and chemical barriers, reducing transition-metal dissolution and electrolyte decomposition [3]. The advent of low-temperature imidized systems allows coating processes compatible with electrode manufacturing that previously required curing above 300 °C [4]. This enables practical integration into cell fabrication without excessive energy input.

Parallel progress in water-soluble polyimide varnishes represents a notable environmental and processing breakthrough. Traditional solvent-borne varnishes employ N-Methyl-2-pyrrolidone (NMP) or N,N-Dimethylformamide (DMF), both hazardous and tightly regulated, but water-soluble polyamic acid precursors enable low-VOC, eco-friendly alternatives [5]. These aqueous varnishes reach comparable mechanical and electrical performance through controlled particle dispersion and crosslinking technology. High-performance formulations exhibit strong adhesion, scratch resistance, and dielectric stability similar to solvent-based systems, aligning with the global move toward sustainable coatings [6].

Manufacturers and researchers are exploring techniques including self-limiting electrospray deposition (SLED) to apply porous polyimide films as separators and protective electrode layers. These coatings maintain thermal integrity to roughly 350 °C and achieve discharge performance comparable to commercial polyolefin films, promoting longer battery life and improved safety margins [7]. As lithium-ion batteries evolve toward high-energy chemistries with nickel-rich cathodes and silicon-dominant anodes, the application of polyimide varnishes is likely to expand, offering low-defect coating uniformity, tolerance to severe voltage conditions, and compatibility with next-generation waterborne processing.

Water-soluble polyimide varnish technologies combine environmental compatibility with inherent advantages of endurance and thermal stability. This convergence of performance and sustainability positions polyimide varnishes as indispensable in advancing electrode coating strategies for durable, high-power lithium-ion batteries that meet both performance and ecological demands.

Seeking more information about polyimide varnishes? Reach out today for an initial consultation.