Technology Spotlight: Episode 19

Biphenyl tetracarboxylic dianhydride (BPDA) offers the most versatility for polyimide synthesis.

Image: Shutterstock

Biphenyl tetracarboxylic dianhydride (BPDA) is a key aromatic dianhydride, produced in both symmetric (s‑BPDA) and asymmetric (a‑BPDA) grades, for high‑performance polyimides used in electronics and aerospace applications [1,2,3]. These isomers let formulators tune rigidity, crystallinity, and processability to meet demanding thermal and mechanical requirements[1,4].

BPDA was introduced as part of the evolution from early PMDA/ODPA systems toward higher‑temperature, higher‑modulus polyimides tailored for microelectronics and advanced composites [3,5]. Symmetric 3,3′,4,4′‑BPDA (s‑BPDA) gives relatively linear, semi‑rigid chains that can crystallize, while asymmetric 2,3,3′,4′‑BPDA (a‑BPDA) introduces a bent backbone that suppresses crystallinity and typically increases glass‑transition temperature (Tg) versus its symmetric analogue [1,2,4].

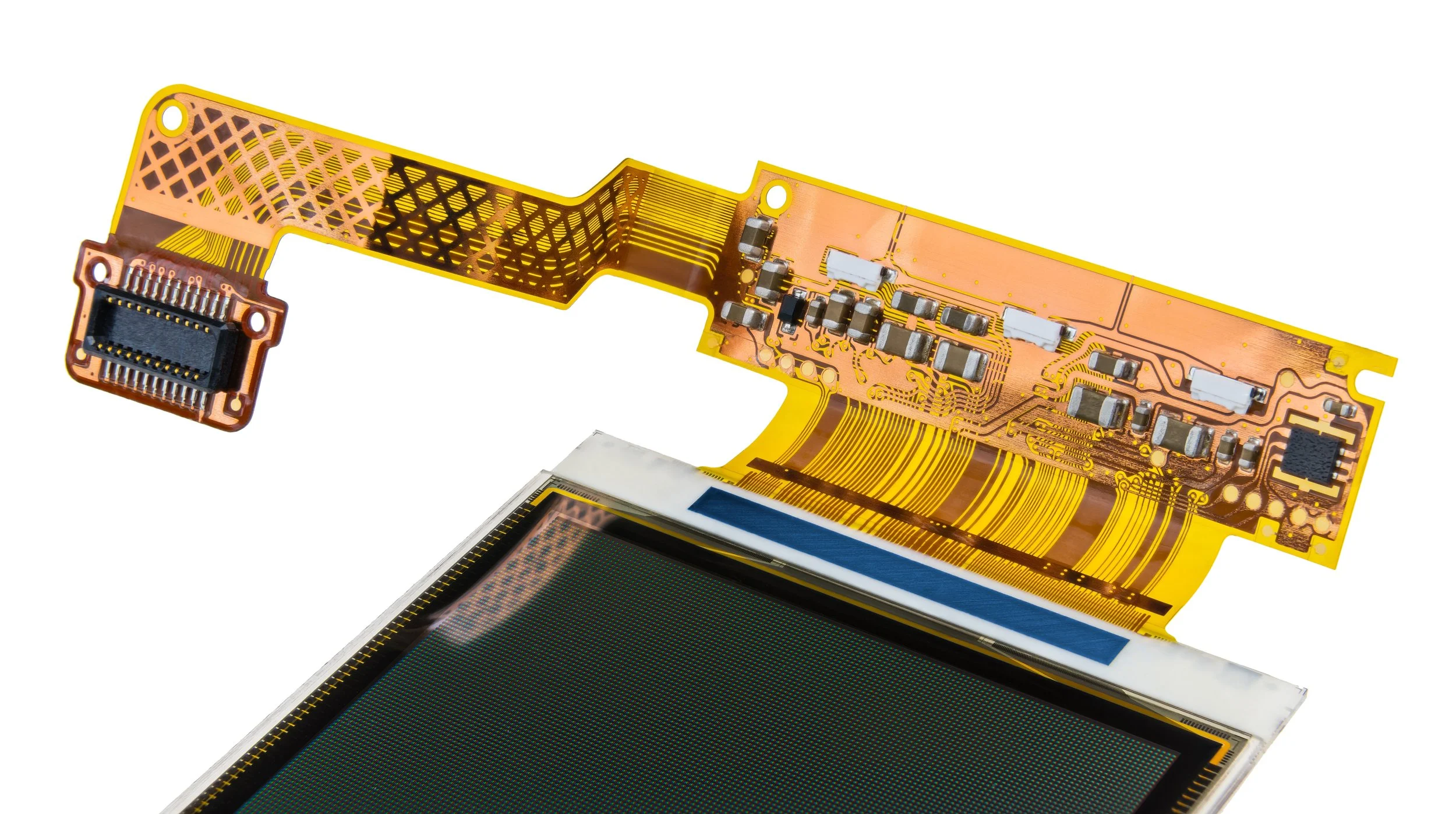

BPDA’s dominant use is in high‑temperature polyimide films, varnishes, molding powders, and composite binder resins [3,7]. When combined with aromatic diamines such as ODA or PDA, BPDA-based polyimides provide high heat resistance, stiffness, and low dielectric constant, making them mainstays in flexible printed circuits, coverlays, flexible displays, and high‑temperature wire enamels [3,6,7]. Symmetric grades are widely used for semi‑rigid films and fibers, while asymmetric grades are favored where higher Tg, amorphous morphology, or improved processing are required [1,4,8].

s-BPDA generally yields polyimides with better toughness and dimensional stability than with PMDA, improving processability at an increase in monomer cost, tenfold with a-BPDA [3]. Compared with ODPA, BPDA increases aromaticity and Tg, trading away some flexibility and impact strength for higher modulus and thermal resistance[3]. Against fluorinated 6FDA, BPDA‑based systems are less soluble and less easy to process from solution, but offer superior mechanical strength and creep resistance at high temperatures, so they dominate in structural films and composites rather than ultra‑soluble optical grades [3,6].

Commercial BPDA is produced by a relatively small group of manufacturers, mainly in Japan and China, tightly linked to the global polyimide value chain [5,7,9,10]. These include:

UBE Corporation (Japan) – Major supplier of high-purity s- and a-BPDA [9,10]

Mitsubishi Chemicals (Japan) – Supply BPDA via affiliate Shinryo Corporation[3,5]

Chinatech, Shanghai Guchuang (China) – Significant capacity for in-country demand.

The market is effectively oligopolistic, with strict purity and traceability requirements for electronics and aerospace customers [5,9,10].

BPDA demand tracks growth in polyimide films, varnishes, and composites used in electronics, EVs, and aerospace [7,9,10]. Recent analyses project the market growing from roughly USD119–245 Mio in the mid‑2020s to USD 189–400 Mio by the early 2030s, a CAGR of 6–7%, driven by flexible electronics, 5G hardware, high‑temperature wiring, and lightweight aerospace structures[5,9,10]. Both symmetric and asymmetric grades are expected to grow, with a‑BPDA gaining share where very high Tg and amorphous morphology are critical, while s‑BPDA remains entrenched in legacy film and composite systems [1,4,9,10].

Looking for guidance on how to use BPDA? Reach out today for an initial consultation.